DfT Solution

Design for test

La DfT peut être trouvée sous différentes appellations, Design for Testing, Design for Test, ou encore Design for Testability.

Chez Tame-Test, nous parlons de Design for Testability.

Les produits à dominante électronique comptent chaque fois plus de composants, ensembles et sous-ensembles. Cette complexité requiert d’optimiser leur testabilité, imposant une phase de Design for Testability, ayant pour but d’adapter le design de votre produit à la stratégie de test définie en amont.

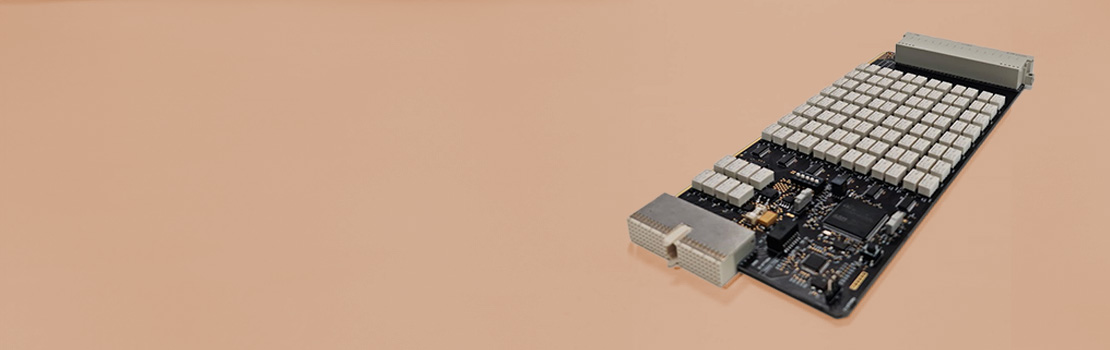

Tame-Test réalise le Design for Testability (DfT) à différents niveaux : cartes, sous-ensembles et ensembles.

Description

DfT Solution : analyse hardware

Tame-Test s’appuie sur les logiciels TestWay Express et TW System, notre expertise nous permet alors d’optimiser les accessibilités, les PCB et les schémas.

Nous mettons en avant et exploitons les possibilités offertes par le boundary scan (JTAG).

Ces logiciels mettent en avant les lacunes, Tame-Test réalise ensuite une analyse et soumet des préconisations pour améliorer la testabilité du produit.

Un rapport de couverture test optimisée suivant nos préconisations vous est ensuite transmis.

DfT Solution : analyse software

Tame-Test analyse si un ajout de fonction est nécessaire dans le soft applicatif ou si un soft embarqué dédié au test doit être développé.

L’objectif étant de (liste non exhaustive) :

- Mettre le produit dans un état donné

- Créer des autotests

- Tester des blocs fonctionnels

DfT Solution englobe :

- Les études du produit, des composants et des ensembles

- Le rapport de testabilité et de préconisations

- La matrice (méthode PPVS) de la couverture de test des test structurels et fonctionnels

- Des rapports réguliers permettant de suivre l’évolution des différentes étapes du Design for Testability

Bénéfices

Testabilité optimale du produit

L’objectif d’une bonne testabilité est de détecter d’éventuels défauts le plus en amont possible dans la chaîne de production, grâce à une couverture de test hard et soft optimisée.

DfTSolution vous apporte son expertise dans ce domaine.

Réduction des coûts de non-qualité

La prise en compte de l’aspect test d’un produit à toutes les étapes est un atout majeur pour l’optimisation du prix final de votre produit.

En effet, dès les phases de conception, les réflexions sur le test doivent être intégrées afin d’adapter le design pour une testabilité optimale. En liant la phase de conception à une réelle stratégie de test et à des équipements adaptés, vous optimiserez votre process de fabrication en réduisant les coûts de non-qualité.

Cette couverture optimale permettra également une réduction importante de vos retours SAV.

Tame-Test a d’ores et déjà réalisé un échantillonnage de produits confiés par les clients de TRONICO afin de faire l’exercice d’une analyse de design for testability par DfTSolution et l’hypothèse d’une stratégie globale par ScopeSoution. Le retour sur investissement est quasiment instantané.

Pour aller plus loin : En plus de ces prestations DfTSolution, nous proposons une analyse complète incluant la fiabilité des composants et des produits.

Ressources

Capital Humain

DfTSolution permet d’intégrer à chaque projet, une équipe d’ingénieurs et techniciens qui connaît les tenants et aboutissants de l’industrialisation du produit. Celle-ci rédige, en étroite collaboration avec les concepteurs (interne ou externe), un rapport de testabilité et de préconisations prenant en compte la complexité des produits et du process de fabrication.

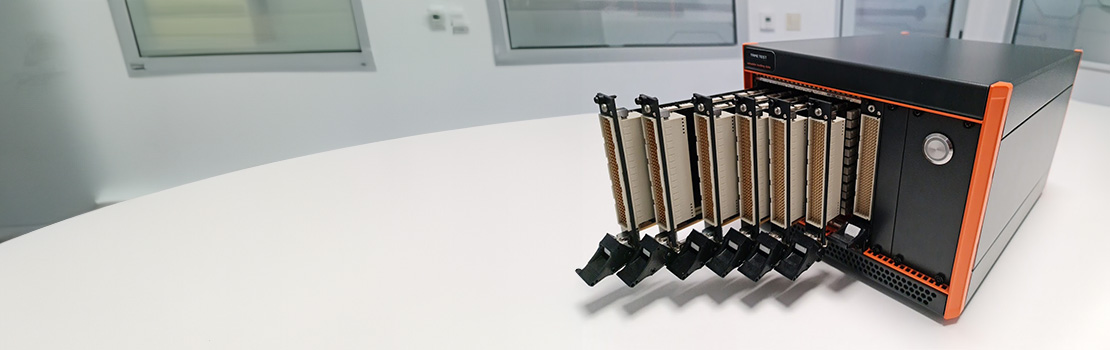

Équipements

Tame-Test s’appuie sur des logiciels d’experts spécifiques au domaine du test :

- TestWay Express

- TW System

Ces logiciels sont enrichis par notre expertise et expérience en incorporant des scripts personnalisés par Tame-Test.